|

|

|

|

|

||||||||||

|

|

|

||||||||||

|

Technical

Tips from Mark W. Persons |

|

If you have any "new old stock"

tubes that are more than 3 years old, it is best to run the filament for a maybe

two hours before putting them in service with high voltage. This will

clean up the tube and will avoid problems from gas arc-over.

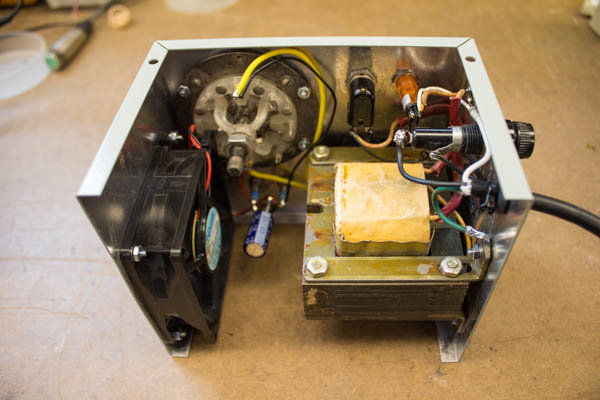

Shown here are two 4CX250B tubes undergoing this treatment on the bench. A filament transformer is connected, via clip leads, to the filament pins of each tube. A variable AC power supply is used on the primary of the transformer to set the filament voltage to exactly 6.0 volts, which is the rated filament voltage for this model number. A digital meter is used to verify voltage at each tube. An important aspect of this is the fan, which is cooling the tubes during this procedure. Lack of proper cooling could cause tube failure. After two hours, they are ready for use in a transmitter. |

|

You could build it all into

box and call it a "Tube Conditioner."

This makes it much easier to do the work. The project includes two blue colored tip jacks for metering the filament voltage. |

|

Included in this box is a 12 VDC

fan which gets its power from the 6 volt AC filament transformer.

That power goes through a bridge rectifier and capacitor to give enough DC voltage to run the fan and cool the tube.

|

|

The stories go on and on.

Stop in again sometime. I'll leave the soldering iron on for you.

|

|

Questions? Email Mark Persons: teki@mwpersons.com |