|

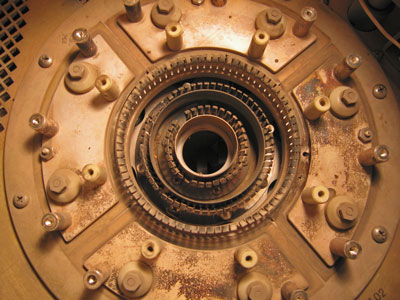

Here is

the socket with the screen contact ring removed. Something looks a

little funny on the left side of the right-hand screen bypass capacitor.

Click

on the photo for a larger view. |

|

Sure

enough, the dielectric material has failed causing a short circuit in

the screen circuit. You can see the arc-through near the top.

Fortunately there was a spare part at the site.

In this transmitter repair adventure, that

screen bypass was not the only problem.

Click

on the photo for a larger view.

|

|

The

entire tube socket had to be removed for bench repair. Note the

scattering of parts in the bottom of the PA cabinet. A piece of

cardboard was placed over the incoming air duct to keep parts from

falling into the cooling fan.

Click

on the photo for a larger view. |

|

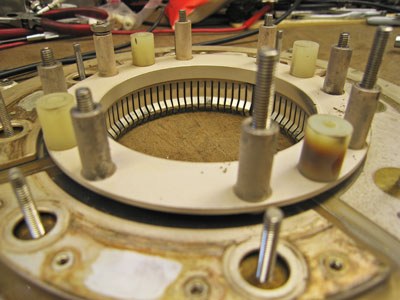

On the

bench, a nylon spacer was discovered as the cause to why control grid

voltage went to near zero at times causing sudden PA overloads.

You can see it discolored brown and black on the right side of the

socket. Since those are no longer readily available, I used a

porcelain insulator as a replacement.

Click on the photo for a

larger view.

|

|

After

the spacer was replaced, the tube socket needed to be reassembled.

It is extremely important to get the socket contact rings aligned

properly. Failure to do so could cause undue physical stress on

the tube causing an air leak at one of the seals and tube failure.

The best way to get

the alignment right is to use a tube. Tighten the hardware as much

as possible, then remove the tube and do the final tightening.

Recheck to make sure the tube fits easily into the socket.

Click

on the photo for a larger view.

|

|

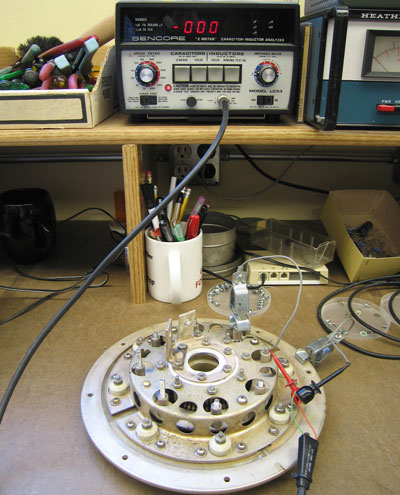

Here the

socket insulators and bypass capacitors are being tested with a Sencore

Z Meter to see if there is any leakage at 600 Volts.

Click on

the photo for a larger view.

|

|

Back in

the transmitter, the screen ring had to be installed and tightened after

the rest of the socket was in place. Again, the tube was used as a

jig to get the alignment right. Also, you can never have too many

tools. A right-angle screwdriver with ratchet was ideal for final

assembly.

Note the black line on

the socket and transmitter cavity. That helped get parts back in

the original orientation. You can get into real trouble in a hurry

if you don't think it all through first and mark the way as you go.

This kind of project

is not for the faint of heart.

Story from October

2009 at KMFY Radio in Grand Rapids, MN.

Click

on the photo for a larger view.

|