|

|

|

|

|

||||||||||

|

|

|

||||||||||

|

Technical

Tips from Mark W. Persons |

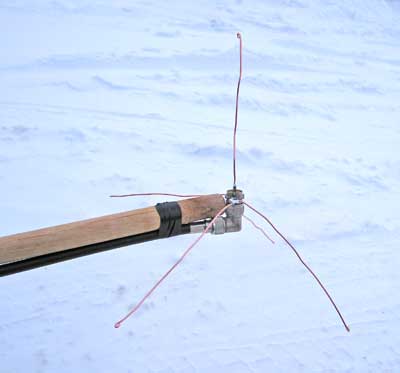

This is a custom temporary 450 MHz antenna that I built in 30 minutes while on the job recently. The antenna was needed as a quick replacement for a commercial antenna that had failed. A day-long broadcast was planned at KIKV Radio in Alexandria, MN, and they could not do it without some kind of a receiver antenna at the studio, which was four miles from the remote broadcast site in town. Their 450 MHz remote pick-up link is very similar to our ham radio equipment. It uses +/- 5 KHz frequency modulation and runs about 20 watts. I first went to the local Radio Shack store to see if they had a scanner antenna, but they no longer stock them. Then, I asked for an SO-239 connector. That is a chassis-mounted connector that you plug a standard PL-259 UHF connector into. Radio Shack did not have one of those either. After rummaging around in my service truck, I found an SO-239 connector, but it did not have the traditional 4 holes so that 4-40 or 6-32 hardware could hold it to a panel. Instead, it required a single hole and was designed to hold itself to a panel with a large nut. That complicated things a bit, but did not prohibit the antenna from being built. Using the formula, 983 divided by the frequency in MHz, I determined the length of a full-wave at their frequency in feet. The antenna is a quarter-wave ground-plane so the element lengths were one-quarter of a wavelength, which is about 6.5 inches. As you can see, an RG-8A/U cable is connected to a right-angle UHF adapter, which then plugs into the bottom of an SO-239 connector. Bare #12 copper wires are soldered onto the connector. The four radials are a 1/4 wavelength also. Each one droops down at about 30 degrees from the horizon, which gives a better match to the line. Originally, I cut the center/vertical wire a little long in case the calculations were not correct. Well, the calculations were correct and I shortened it to give the lowest VSWR (Voltage Standing Wave Ratio) at the frequency of interest. As an added touch, I made the wires long enough so the ends could be folded back to reduce the likelihood of injury, especially eye injury, when working around the antenna. For me, this was a temporary antenna, which was not rugged enough to handle a bad weather. Also, it was not treated to keep water out. The antenna was mounted to a wooden flag pole and temporarily attached 20 feet up on a tower. A month later, it was replaced with a new commercial antenna. |

|

The stories go on and on.

Stop in again sometime. I'll leave the soldering iron on for you.

|

|

Questions? Email Mark Persons: teki@mwpersons.com |