It seems that every time we turn around

there�s another power problem to solve. We may be radio broadcast

engineers but we need power to keep a station on the air.

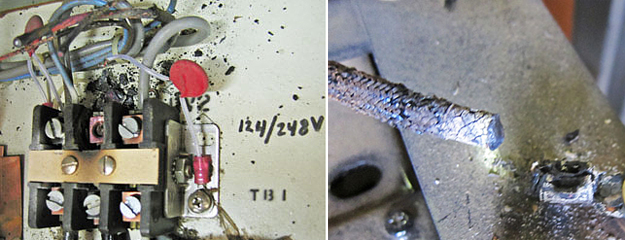

Fig. 1 is from the inside of a broadcast transmitter where 240 VAC

power comes in. A loose connection

on the power connector block caused wires to burn off. Wires have

been pulled back from the top center terminal of the block to show

the debris left from the incident. Insulation burned off the

overheated wires for about two inches from the block. The connector

will need to be replaced after a temporary repair is made.

|

|

Left: Fig. 1, Right:

Fig. 2 |

|

The photo shows a Harris HT-5 FM but this kind of problem can and

does happen to all transmitters where high-current conductors are

terminated. Best to check tightness of these kinds of connections

whenever practical.

Fig. 2 shows a similar incident in a Continental 816R 20 kW FM

transmitter. A heavy 208 VAC wire on the primary of the high-voltage

power transformer is burned off.

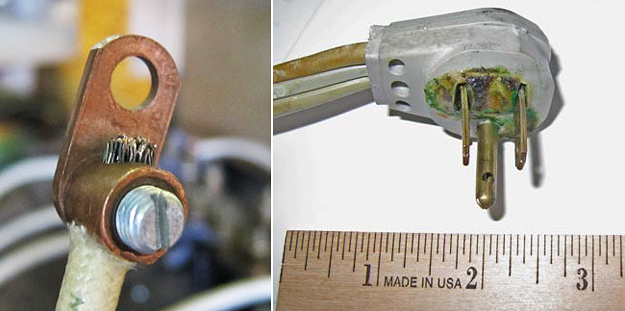

I have seen this twice over the years. The original crimped terminal

gets warm and then hot as resistance increases. The wire often needs

to be cut back five inches or more to find clean copper. A field

replacement can be a screw terminal as shown in Fig. 3.

Fig. 4 shows a 120 VAC plug that was providing power to three

equipment racks in the engineering area of a radio station. The

cable-to-plug wiring developed higher-than-normal resistance

resulting in overheating. The insulation on one conductor turned

brown from the heating. As you can see, the plastic on the plug

suffered as well.

|

|

Left: Fig. 3, Right:

Fig. 4 |

|

The problem was caught on a routine inspection when it was noticed

that the plug was running hot. This plug would have gone into total

failure after not too much longer. The wall outlet didn�t look very

good either.

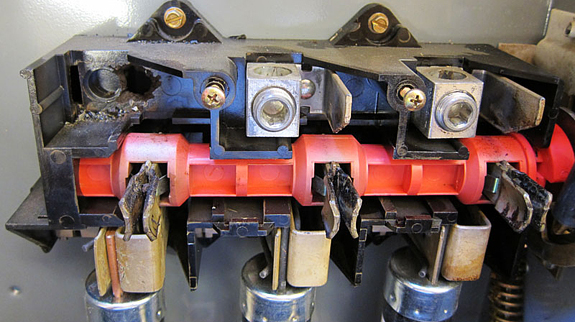

Fig. 5 is the top/input end of a three-phase/200 ampere fused

disconnect switch used at a transmitter site to provide 240 VAC

power to a 25 kW FM transmitter. The leftmost lug is missing because

of overheating. The left fuse was replaced temporarily because it

failed from heat fatigue. The center and right fuses are discolored

and also were discarded after the switch was replaced because it is

good engineering practice.

The lesson here is that reliability is more important than saving a

buck.

|

|

Fig. 5

|

|

The panel was a Square D model D324N. It had been in service for

just nine years. Two years earlier, an identical panel was replaced

on another transmitter at the same site.

That is a bad track record considering less than 120 amperes of

current were being drawn per leg. Electrical practices dictate that

loads should be no more than 80 percent of the capacity of the

panel. In this case, 120 amperes is just 60 percent of 200 amperes.

That should be plenty of safety margin. I suspect that Square D had

a problem with this panel design. The replacement panel was made by

Siemens.

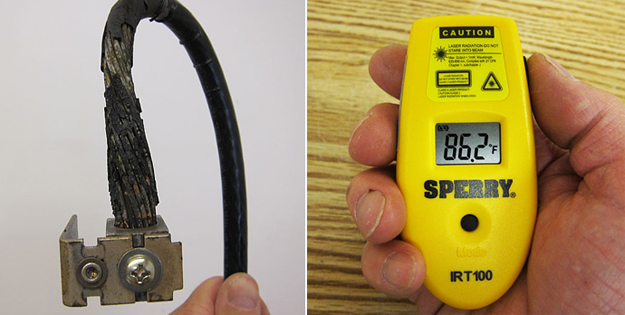

Fig. 6 is the left input lug of that same panel after it was gently

lifted out. The 3-0 wire connected to it had overheated and its

insulation was largely fried off. Not only did the fused disconnect

need to be replaced, but the wire leading to it needed to be

replaced.

There are inexpensive infrared thermometers that can spot

overheating problems before they become big. Fig. 7 shows a Sperry

IRT100 temperature sensor, with laser pointer. It was less than $50

from the local Home Depot store. The moral of the story is that

preventive maintenance can save you problems later.

|

|

Left: Fig. 6, Right:

Fig. 7 |

|

|