|

|

There you are, driving along and minding your own

business while chatting on 2 meters.

Then you spot lightning ahead.

Your thoughts immediately turn to your

HF ham station (mine is in Photo A).

“Did I remember to disconnect the

antenna from my rig?”

“Should I turn back or continue on?”

Well, if you had constructed and installed an automatic

antenna relay, your rig

would be safe.

I

built just such a device for that very reason for use on coaxial

cables.

A DPDT relay connects my linear

amplifier to a 5-position antenna switch when the rig is on.

When off, the amplifier’s RF center

conductor is disconnected from the antenna and connected to

ground, and the antenna center conductor goes to ground as well.

That is triple protection.

|

|

|

|

|

Photo B. Connector end of the antenna relay

box.

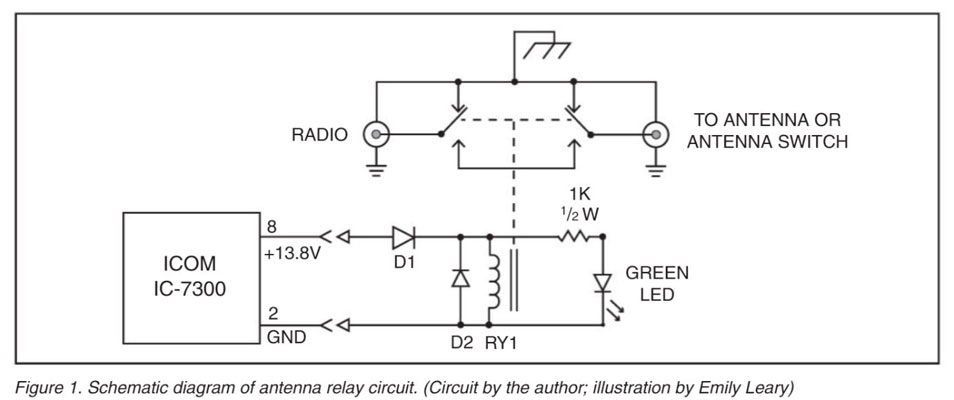

The project revolves around the capabilities of a Potter

& Brumfield/Tyco Electronics PRD-11DY0-12, DPDT 12 VDC relay.

It has silver plated contacts with a

rating of 20 amperes at 277 VAC (781 volts peak to peak).

For perspective, 1500 watts into 50 ohms

is 5.48 amperes with 274 volts RMS.

Peak-to-peak voltage is 772 volts.

As a radio broadcast engineer, I

successfully used this relay at 1-KW AM broadcast stations over

the years.

It was perfect for selecting a main or

auxiliary transmitter to the antenna.

Never had a problem.

The antenna relay needs 12 VDC power that is on only

when the transceiver is on.

Not all rigs can do this.

In my case, power comes from the

accessory connector of my Icom IC-7300.

It has a 13-pin DIN connector with power

output only when the rig is on.

I found a used connector in my junk box

and joined it to a two-conductor cable.

The current is fairly low, as only 169

mA is required to run the relay coil, plus 10 mA for the LED

lamp.

There is a diode across the relay coil to prevent the

relay from producing a voltage spike the instant power is shut

off.

This sort of EMF transient could damage

the device that is powering the box.

I originally started with a fuse in

series with the power, but later switched to a diode to “steer”

power to the relay.

Lacking that, accidentally connecting

the 13.8 volts backwards would have looked like a short circuit

because of the diode across the relay coil.

The parts list is in the sidebar. Small items came from

my junk box and hamfests. The box I chose is as small as

practical to house the relay.

You might prefer something else.

Let me remind you that the box should be

metal, as opposed to plastic or PVC.

The goal is to keep RF radiation inside

the box to prevent harming someone.

I drilled four more holes for screws to

increase mechanical integrity and to help keep RF inside.

Parts List with prices for the larger items:

1 –

P&B/Tyco Electronics PRD-11DY0-12, DPDT, 12 VDC relay, $57.55 at

Digi-Key

1 - Hammond 1411L, 5” x 4” x3” grey aluminum utility

box, $12.38 at Digi-Key

2 - SO-239 chassis mount connectors

1 - Green LED indicator with mount

1 - 1 K ohm/half-watt

resistor

2 - 1N4004 diode

1 - Accessory connector for the

rig

Building the Relay

Please refer to the photos as we discuss the

construction of the relay, starting with Photo B. The schematic

is in Figure 1. The antenna relay described here is not

high-tech.

It is an easy project that almost any

ham can tackle.

My advice is to take time and pride in

the final result.

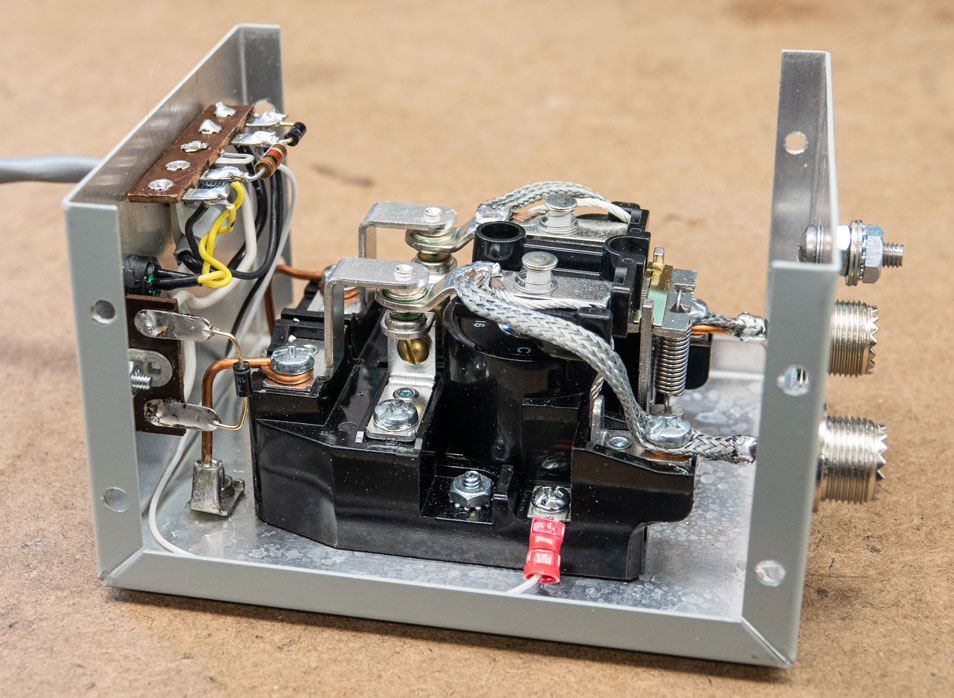

Photo C gives us a look at the inside of the box. Use

good judgement, along with a ruler, to center the relay and

connectors in the chassis for a clean appearance.

A drill press was used, but you could

get by with a hand-held drill if you are careful.

I sometimes drill a small pilot hole for

position accuracy, then enlarge with a larger bit.

|

|

Photo C. Inside the

relay box.

|

|

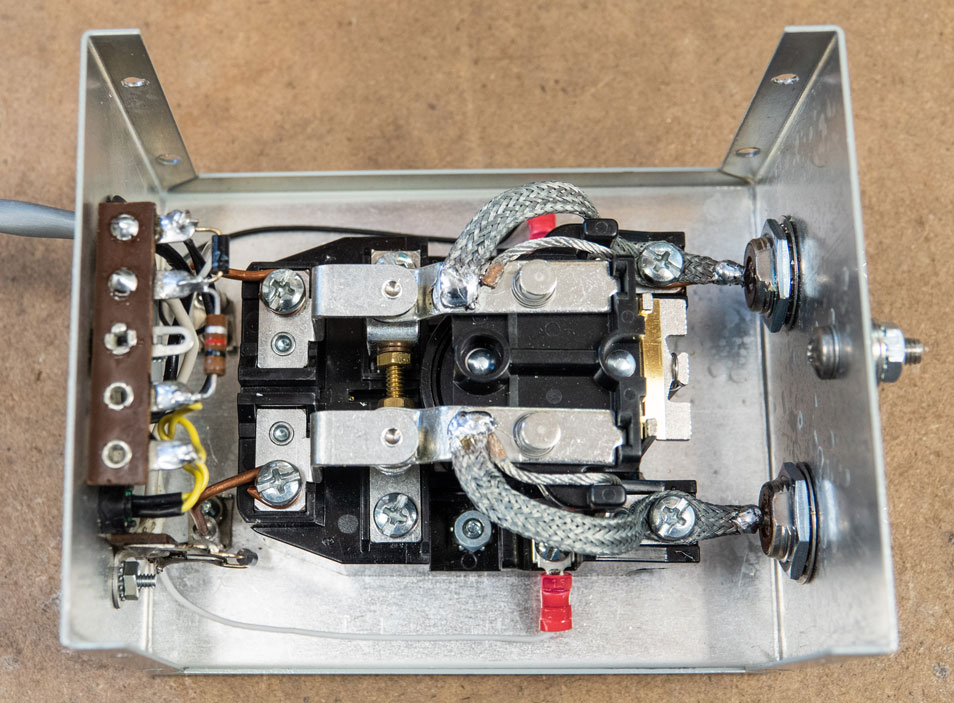

Taking a look at Photo D, the relay's RF connections are

1-7/8 inches apart, so it was logical to use the same spacing

for the SO-239 connectors.

Starting with a 1/4-inch hole, I used a

5/8-inch chassis punch for the SO-239 connectors.

From there, #12 solid copper wire runs

to the RF relay.

It is easy to do and is good for 20

amperes of current … at least at DC, but it is a little less at

RF frequencies.

I used crimp-terminals on the ends of

the two wires that go to ground.

Instead of crimping, I soldered them on.

The idea behind the terminal is to avoid

a situation where dissimilar metals (copper and aluminum) are

bolted together.

Corrosion could compromise the

connection, especially in a humid environment.

Keeping RF lead lengths short is very important for low

VSWR.

I started by using a wire between the

two normally-open relay contacts but changed to a brass 6-32

bolt with three nuts and lock washers.

You can see that in Photo D.

Finally, I soldered some 1/4-inch braid

in parallel with the wires on the relay armature and out to the

SO-239 connectors.

This further reduced inductance.

Testing confirmed the braid did not

hamper mechanical operation of the relay.

|

|

Photo D. Top view of

the box showing a brass bold joining normally-open (N.O.)

contacts on the relay.

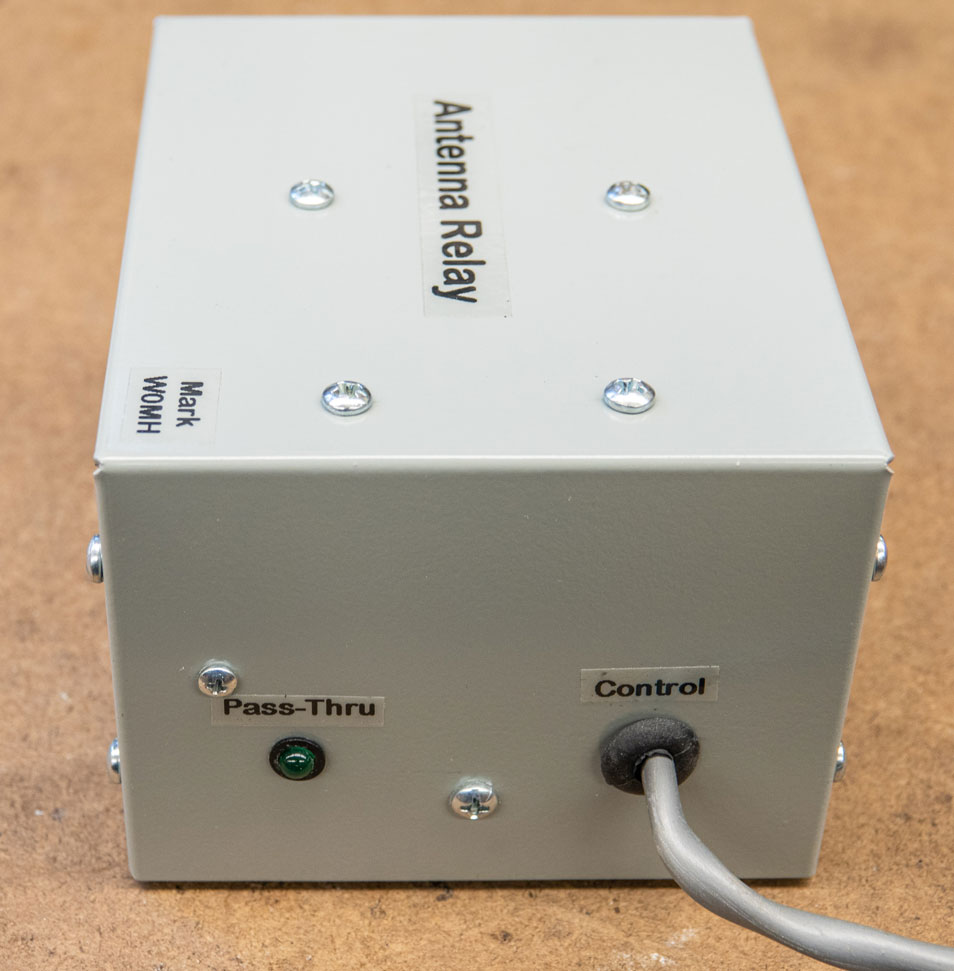

In Photo E, a green LED indicates the relay is allowing

RF to pass through.

As an added touch, I added four stick-on

feet, not shown in the photo.

You’ll notice I used a 10-32 bolt as a ground point near

the RF connectors.

This should be connected to

station ground, along with your rig and other station equipment.

That’s just good practice in any ham

shack.

Retain a copy of this article, or your

schematic version of this project, in station files for future

reference.

|

|

Photo E. Side of box

showing the LED and control cable.

|

|

Pass-through power loss is very low with this design.

Return loss measurements showed the VSWR

was 1.01:1 on 160 meters, 1.02:1 on 80, 1.03:1 on 40, 1.04:1 on

30, 1.05:1 on 20, 1.06:1 on 17, 1.07:1 on 15, 1.08:1 on 12,

1.09:1 on 10, increasing to 1.17:1 on 6 meters.

I don’t recommend this configuration for

use above 54 MHz.

In my opinion, it is a small price to

pay for the security the relay affords.

It’s

your choice.

There is one thing … this relay protects ham equipment

from high voltage between the coaxial cable shield and inner

conductor.

It is effective when the antenna coax

shield is tied to the building electrical service

entrance/electrical panel ground.

That arrangement is known as a

single point ground where

lightning will want to go to ground at that point, rather than

going to the radio equipment.

Think of the rig as a “stub” from the

service entrance.

It gets power and RF from the same

ground point.

There is no reason for lightning to go

there.

An additional ground at the shack is a

bad choice because then the radios can be in the lightning path

to ground.

I now have much more confidence, knowing that my rig is

as safe from lightning as I can make it, without the hassle of

disconnecting the antenna after each ham session.

|

|

|

Note:

Mark Persons W0MH is a retired radio broadcast engineer.

He was first licensed as WN0AXD at the age 15 in 1962.

Mark received the Engineer of the Year award from the

Society of Broadcast Engineers in 2018 and their Lifetime

Achievement Award in 2020.

He currently mentors four radio broadcast engineers and

is a member of the National Radio Systems Committee, which

developes improved technical standards for radio broadcast with

ultimate adoption by the FCC.

01/03/2022 Email:

Hi Mark. I read your article in the October 2021 CQ Magazine

about the antenna grounding relay and my first thought was

“Well, Duh!” That thought was prompted by the fact I had

everything required to build the project in my junk box and that

I had, several years ago, built a similar project to

automatically ground my ladder line fed 80m loop, though that

relay was mounted in a non-metallic box. Thank you for a well

thought out and well written article. And thanks for the

impetus to get into the shop and actually build the project. 73,

Ron NY0A, Dassel, Minnesota.

|

|