|

DAs are marvels of engineering but can seem daunting. Here are useful

tips!

Our previous

article

Find Your

Modulation Sweet Spot,

published in the Oct. 9, 2019, issue of Radio World, sets the stage for

a two-part discussion of AM directionals, beginning here.

As you surely

know, fewer engineers are qualified to work on AM directional antenna

systems today. Younger ones who maintain these marvels of engineering

may not be as well versed as their predecessors. If you are a

member of the new breed, my advice is to be careful not to do the wrong

thing when tackling a problem. Don't make adjustments without analyzing

a situation first.

|

Fig. 1: A 1960s phasor with commonpoint controls added.

|

PROBLEMS

If you find antenna monitor phase and ratio readings are off

more than a few degrees or a tower radio is off more than 5%,

then do not start adjusting the phasor to compensate. Keep your

cool. Write down all the phasor dial readings for future

reference. Do a complete physical inspection, including

eyeballing the inside of the phasor cabinet and antenna coupling

networks. Look for broken connections everywhere and on lines

running to the towers. Go out and measure the monitor points.

You may find they are in spec and that your real problem is in

the antenna monitor or other part of the sample system. Jumping

to the wrong conclusion could result in chasing your tail to fix

an antenna problem that you don't have.

TOO MANY KNOBS

An engineer maintaining a two-tower AM directional antenna

station called me for advice recently. He is one of the

engineers I am mentoring. A station's commonpoint impedance (RF

input to the phasor) was difficult to adjust because the

variable commonpoint resistance coil was at one end of its

travel. All had been well a few months before. Today,

solid-state transmitters want to see exactly 50 ohms with near

zero reactance, as you know, so setting the commonpoint

impedance correctly is very important.

As it

turns out, the phasor has phase and ratio controls for both

towers. In this case, it was too many knobs. The ratio

controls could be tweaked on either tower to keep the station in

specs. This led to the commonpoint problem when he used both to

get the correct antenna monitor phase and ratio numbers. The

phasor input matching network was looking at a phasor buss

impedance that was not according to the original plan.

PHASOR

DESIGNS

It's

important to understand how phasing systems are designed and

built. A transmitter feeds RF power into a phasor cabinet, where

there is a three-coil impedance matching network. It feeds

RF energy to a point called the buss. This is where power is

rationed out to phase and ratio controls for each tower. The

buss is rarely 50 ohms, and it is normal to have the impedance

change a bit as an engineer tweaks phase and ratio controls to

maintain FCC licensed specifications. The input matching network

normally has enough operating range to compensate for these

adjustments.

Not all

phasors have a front panel adjusted ratio control for the

reference tower. That is for good reason. The reference tower

normally gets more power than the other tower or towers. There

is normally no need to adjust power to the reference tower after

the station is initially tuned and licensed. It is the

standard/reference that the other towers or towers are

compared/referenced to.

I told

the engineer to carefully adjust the reference tower ratio

control to full, or close to full on, while keeping the other

tower ratio and phase correct. Then, don't touch the reference

tower radio control again. Mark it as don't adjust. That

solved his commonpoint problem. He then had good resistance and

reactance control because the buss impedance was as expected in

the design. Also, running both ratio controls down to their

lower ends could cause some phasor components to run hot.

|

|

Fig. 4: Mark your normal dial settings for easy reference.

|

|

DESIGN

EVOLUTION

Phasor

systems did not typically have front-panel adjustable input

matching networks years ago when tube transmitters were the

norm. That changed when solid-state transmitters came along. Now

input resistance and reactance controls are required to keep

reflected power low and transmitters happy.

Fig. 1

shows a 1967 vintage Gates three-tower phasor. It did not

originally have an input matching network that is adjustable

from the front panel. I added those knobs to help control the

input impedance and transmitter power when switching from 5 kW

non-directional day to 5.4 kW directional night. One control is

for resistance, which is tweaked to keep the input at the

licensed 50 ohms. The other is commonpoint reactance. Fig. 2 is

the dial I normally adjusted to get the transmitter to make just

the right amount of power at night.

In this

case, the day non-directional antenna coupling unit has clips on

fixed coils for adjustments. Once set, it was good to go. The

maintenance procedure is to get the transmitter running at the

correct power level in the day mode, then switch to night and

adjust the night commonpoint reactance control to get the

correct directional antenna power. It is that simple.

You'll

also note there are FCC-required operating parameters listed on

the front of the phasor and transmitter. They are right where

needed most.

Yes,

that is a Gates BC-5H Transmitter next to the phasor. It has

been in full service, running 5,000 watts day and 5,400 watts

night since 1973. That's 46 years! This transmitter is on its

third high-voltage transformer, third set of AC contactors,

fifth set of high-voltage rectifiers and the solid-state audio

driver section has been rebuilt four times on site without

sending it to a factory for repair. The transmitter lives on,

but will likely be replaced by my engineering successor when the

next serious failure occurs. Fortunately there is a Collins 5 kW

AM to back it up. Both are excellent tube designs.

ANTENNA

EFFICIENCY

Can you

assume that all is well when the monitor points are below FCC

limits? Not necessarily. You might have serious impedance

mismatches and power divider mismatches, as described above. RF

power could be turning to heat.

You can

get a readout on antenna efficiency by going to the original

proof of performance documentation and making six or more

measurements in the major lobe or lobes. The readings should

agree, although there are seasonal variations. RF travels better

over frozen ground so winter signals are inherently a bit

higher. It is not a big deal in the first couple miles from the

transmitter. Ground loss changes become more apparent the

further out you go, especially at 20 miles and beyond.

OOS, OOM

Just

because the phasor doesn't have active components, that doesn"t

mean it should be ignored. Rodents get in sometimes and need to

be dealt with. Loose hardware is common on RF contactors because

they are usually operated twice a day with plenty of vibration

in the process. RF contacts wear and should be replaced before

they fail completely.

HEAT

Get one of those infrared temperature

meters and go through the phasor, then antenna coupling networks

looking for hot spots. Use it around electrical load centers

too. You might be amazed to find hot electrical contracts and

wires that are about to fail. Best to take care of the problem

before it causes an off-air emergency at a bad time.

|

|

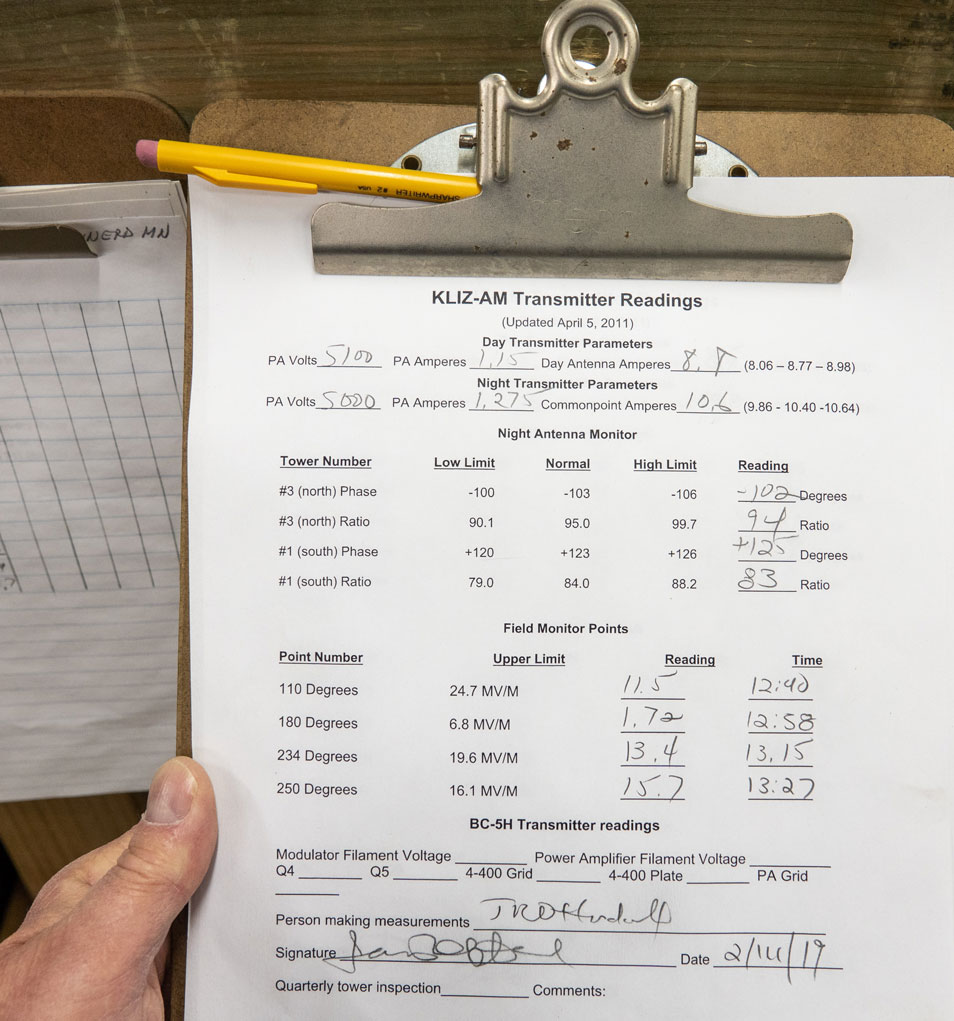

Fig. 3: Keep good records.

|

PAPERWORK

Keep Good visit-to-visit documentation on an AM directional

(Fig. 3). It is a history of how the system has been behaving.

You don't just log that everything is OK. AM directionals have

many parameters to keep track of. That includes phase and ratio

readings on each non-reference tower, dial settings on the

phasor, transmitter PA readings, commonpoint current and monitor

point readings. along with date and time. You'll likely see

seasonal changes on monitor point measurements.

|

|

Fig. 4: A carrier modulated 100% with a 1 kHz sine wave.

|

|

Fig. 4

shows a phasor adjustment crank. Note that normal counter dial

reading is labeled nearby for easy reference. This is one more

way to prevent an "oops" from becoming a major problem.

You

should keep accurate phasor schematic documentation on hand at

the transmitter site. Designs and "as built" are often a bit

different. I recommend you pencil any changes on the original

schematic. Also, mark down the number of active turns on each

coil in the system. As you know, silver-plated straps with clips

are used to short out unused turns on fixed coils. They are set

once and then normally not touched again. It won’t take but an

hour to do the documentation and will save a lot of headaches in

the future. Lightning can blow up a coil or capacitor beyond

recognition. Having parts values and settings on a schematic

diagram can be a life saver.

A nearby

station was visited by vandals one night. Somehow they got into

the antenna coupling networks and pulled clips off the fixed

coils. No other damage, just mischief. It took the engineer only

an hour to put the coil clips back in the right spots, plus do a

little tweaking, to get the antenna system working properly

again. Imagine trying to start from scratch to get the system

operational without that knowledge. Ouch!

By the

way, spare parts and equipment manuals belong where the

equipment is, not back at the studio. That includes books and

programming information for remote control systems.

The best

is yet to come. Stay tuned for an upcoming issue, where you'll

find a real-life story about a 197-foot tower that came down in

the parking lot at a directional AM station.

On to Part 2 of this

article

|

|

Comment

on this or any article. Write to radioworld@futurenet.com.

Mark Persons, WØMH, built four new AM

directional systems, from the ground up, using only schematic

diagrams and parts. He is an SBE Certified Professional

Broadcast Engineer and was named SBE Engineer of the Year in

2018. Mark is now retired after more than 40 years in business.

His website is www.mwpersons.com.

Email Tuesday, January 7, 2020:

Enjoyment of Directional Antenna article in Radio World

Magazine. Hi

Mark. Just thought I'd write a few lines expressing enjoyment

over reading your recent article in R/W on directional

antennas. The first station I worked at was in Cleveland ,

Ohio, (WHK-AM/FM) was back in 1964+. We had a 3 tower array and

I learned a lot (some of it the hard way) at the station--such

as RF burns from a nearby 50 KW ND AM nearby which picked up RF

while doing doghouse measurements at nite...the good old days!

Got a chance to talk with consultant Carl Smith, who worked

nearby. He really knew antennas and directional arrays.

Take care...look forward to future articles. 73s. Steve Molner, W8ANJ, North Ridgeville, Ohio, USA

|

|