|

It is easy to

do the minimum on a job. You’ve

seen it happen, and so have I.

Sloppy work degrades an

installation and can be an

eyesore. Ultimately, it can

become a “house of cards” that

collapses upon itself. Why

should anyone settle for that?

I make a conscious effort to do

clean work, even if previous

work was done poorly in that

location. In essence, I kicked

it up a notch. You should, too.

It’s better to take a little

extra time to do it right the

first time than have to face the

consequences of a bad

installation later.

TAKE PRIDE IN YOUR WORK

|

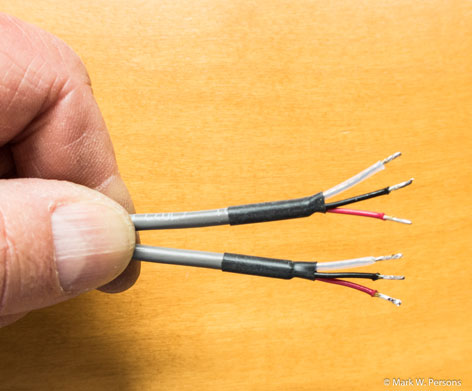

Fig. 1 illustrates a

method of doing clean

installations. Two

shielded pair audio

cables are prepared for

termination. The

otherwise bare shield

drain wire is covered by

clear heat shrink

tubing. Likewise, the

foil shield end of the

cable is protected from

touching something it

shouldn’t by black heat

shrink tubing. It takes

less than a minute to do

the job and is worth it

because it prevents

problems. |

|

Fig. 2 shows two

shielded pair cables

that have been twisted

together to form a

stereo pair. Yes, I know

there are stereo cables

that come from factories

bonded together. The

point here is that heat

shrink tubing is used to

keep the cables from

being separated from

each other. This kind of

organization is the

right thing to do to

avoid confusion later. |

|

Fig. 3: Good grounding

in a wooden rack. |

RACK GROUNDING

Sometimes broadcast

equipment winds up in a wooden

rack. In that case, the

equipment needs to be grounded

more than ever.

Fig. 3 Shows such an

arrangement, in which copper

braid is run vertically on a

cabinet member, then short

jumpers are screwed to the braid

and to each piece of equipment.

The braid was the shield, pulled

from a piece of RG-8 cable. The

jumpers are two-pair audio

shielded cable with all

conductors bared and crimped

into a terminal at each end.

These are larger than normal

size wire terminals because they

have to handle five wires at a

time. The jumpers are short with

rounded corners, not square, to

make it easy for lightning to

follow to ground. The best

practice is for jumpers to have

an insulating jacket so they

don’t cause a problem when

accidentally touched to

something else in the rack.

On that same point, bonding

wires between equipment and a

rack are still proper even when

the rack is metal. Paint on the

rack can, in some cases,

insulate the rack from

equipment. The best choice is to

run a one inch or larger copper

strap on the inside of a rack,

top to bottom, bolted to one

side. Make sure that strap goes

to station ground — you’ll be

very embarrassed if there is

lightning damage, if you haven’t

connected it.

[More Tech Tips: "Yes You Can

Build Your Own"]

|

|

Fig. 4: A custom wood

equipment rack. |

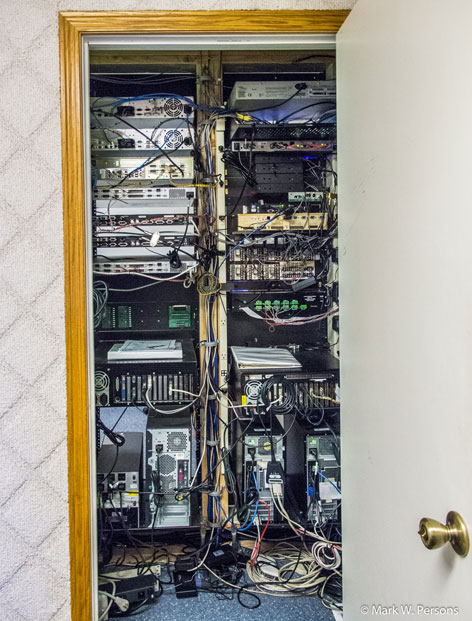

Fig. 4 shows a three-bay

equipment rack system that was

constructed on site with a

minimum of expense. The area

started out as a closet, which

was accessed from the other

side. The wall was partially

dismantled and reconfigured with

metal rack rails.

Middle-Atlantic Products makes

model RRF-45, 78-3/4 inches,

just for this purpose.

Smaller rails are available too.

The rails are L shaped to screw

to the wood sides. They have a

series of drilled and tapped

10-32 holes where 19-inch

equipment can be bolted in.

(Measure twice and cut once when

doing this.)

The station had a carpenter

install three 2x6 studs, side by

side, at each dividing point

between rack bays. The carpenter

left an additional 3/16 inch

between the sides to make up for

errors. Rack rails were then

screwed to the wood with small

flat washers to get the spacing

exactly right. Fig. 5 shows the

closet door open so the

equipment can be worked on from

the back side.

There are plastic cable clamps

used for routing cables and

outlet strips to plug the

equipment into between the rack

bays. Yes, there are grounding

conductors running behind the

wiring too. The photo was taken

after a few years of use, so the

wiring is not as neat as I would

normally like to see.

|

Fig. 5: The back of the

rack seen in Fig. 4 |

STL PROBLEM

This is an interesting

and true tale of hum and buzz in

a 950 MHz STL system. At

first, it was assumed that there

were bad electrolytic capacitors

in the STL transmitter or

receiver. Replacing the pair

resulted in the same problem.

Further examination revealed

that an external 950 MHz RF

preamplifier, at the receive end

of the system, was the cause.

How could that be?

|

|

|

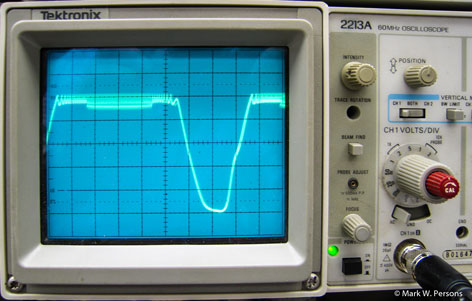

Fig. 6: An STL

preamplifier with a

problem. |

Fig. 7: An oscilloscope

reveals the answer. |

Fig. 6 shows the preamp was

powered by a 12 VDC wall-wart

that has an electrolytic

capacitor inside to smooth out

DC. The capacitor failed by

opening up, resulting in DC with

a high component of AC ripple

feeding the preamplifier. Fig. 7

shows what the supply voltage

looked like on an oscilloscope.

Ouch! The preamplifier, in

essence, turned on and off at a

120 Hz rate, thus the buzz in an

already weak FM STL signal.

SITE CLEANING

You’ve seen it before, a

transmitter site that is

overgrown by brush. There is at

least one good tower contractor

in Minnesota who brings a “brush

hog” to sites when doing

inspections. The operator clears

a path from the tower to each

guy point and then around each

point to facilitate maintenance.

|

Fig. 8 shows a brush hog

clearing around the

transmitter building

too. Nicely done. Hogs

have large tires that

are unlikely to damage

an AM ground system.

Best to stay away from

in front of a machine as

it might throw a rock in

your direction. |

AM ground system damage can be

repaired easily — if discovered

when it happens.

The normal specification for an

AM ground system is 120 #10 bare

copper radials going out for

about 1/4 wavelength like

equally spaced spokes of a

wheel. The usual practice is to

bury them 4 to 6 inches below

the ground surface.

When a copper ground wire is

cut, just grab the ends and pull

them up so 6 inches or more is

showing. Mark them and come back

with a 12-inch or longer piece

of #10 bare copper wire. Twist

the ends together and then braze

with an oxygen and acetylene

torch. You can use a Mapp gas

torch, but they don’t get as

hot.

For brazing rods, I use Sta-Silv

15, which contains 15 percent

silver. You don’t use a lot, so

the cost is not that steep. Do not use

ordinary tin/lead solder. It

will deteriorate underground and

fail.

|

|

Fig. 9: A tower worker

climbing almost to the

moon in the early

morning. |

If you work indoors, you miss

some of the great scenery that

engineers often witness.

Use your head to do the job

right the first time. It makes

perfect sense.

Comment on this or any article.

Write to radioworld@nbmedia.com. |