My preference is to put one at the 50 ohm input and another at the antenna of all antenna coupling networks. They also should be installed in AM phasors where transmission lines enter from each tower. Another good place for one is at the input side of the phasor where transmitter feed lines come in. The idea is to limit the maximum voltage to a safe non-destructive value by diverting excess energy to ground. The project I am describing is on the cheap.

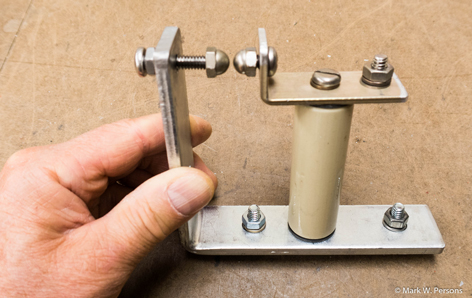

EASY TO DO I used a 1/4-20 machine screw, with lock washer and nut, allows for adjusting the gap dimension without laying hands on RF at the other side of the gap. The smaller L bracket is made of aluminum and is also threaded to accommodate plated brass hardware. I use non-ferrous metals in RF circuits because they will not vibrate at the radio frequency, heat up and sometimes melt. Don't laugh, it has happened in high-power systems. You gotta think about these things! If in doubt, use an ordinary bar magnet as a test tool. You should not use any hardware for RF if it is attracted to a magnet. Yes, the larger angle bracket is steel, but it is not on the RF side; it is on ground and not conducting RF.

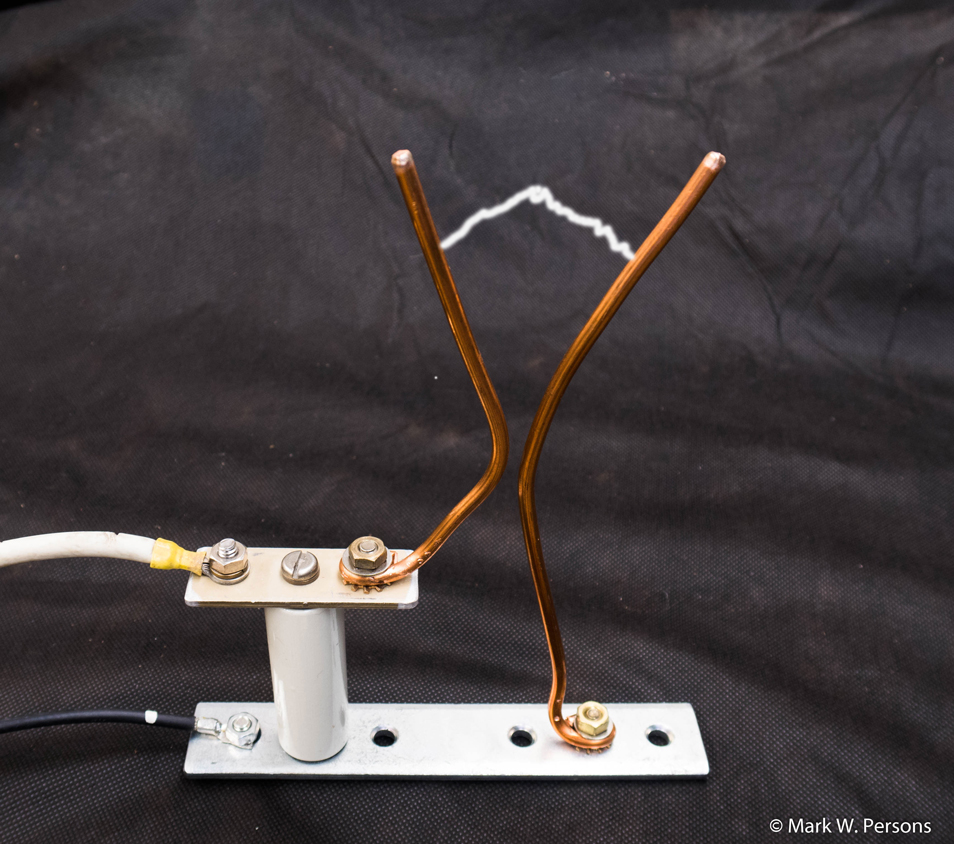

Fig. 2: Arc gaps that anyone can build. A 2x3/4-inch square porcelain insulator is bolted to the two L brackets. The large arc gap has a 3x1-inch diameter insulator. The bottom bolt for each insulator has a flat head and is recessed to be flush with the bottom surface of the bracket. I do this by using a much larger drill bit to provide a bevel where the mounting hole is. Yes, there are fiber or nylon washers at each end of the insulator to help prevent breakage, especially during temperature changes. Porcelain is brittle and it cracks instead of giving. Also, I like to round off corners, if for no other reason than to prevent injury as my hands work on the device. Construction of these devices assumes you are handy with tools and like to build things. Parts for this project came out of my junk box but would cost less than $10 new. Machining and assembly time for each one was about 30 minutes. (Maybe I should have been a machinist instead of a broadcast engineer!) Nice, new arc gaps are available from several sources, including Kintronic Labs (kintronic.com). One of their most popular models is the AG-3-1.5B, which sells for $185.

INSTALLATION & PLACEMENT

Arc gaps of this type should be used inside, not out in the elements. In addition, you want to mount them in such a way that the acorn nuts are horizontal from each other. That will allow an arc to clear quickly. Mounting an arc gap vertically can lead to a continuous arc that does not quench easily. One important attribute of this design is the arc distance is held constant over time because of its rigid mountings. You don't want it to be flimsy and cause problems.

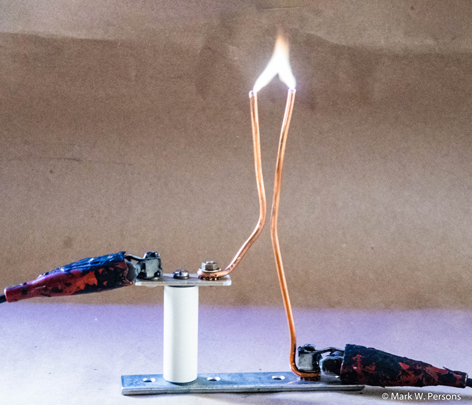

DON'T TRY THIS AT HOME!

SETTING THE ARC GAP For me, it is easier to set the gap wide, then slowly reduce the spacing while the station is fully modulated. It can be an exciting moment when the arc occurs! I then back off the gap to twice the distance and tighten it down.

DON'T WAIT Make it part of your routine maintenance to check all arc gaps for cleanliness. You might be surprised to find gaps badly pitted from arcing. Filing the edges smooth might be required. Be glad they helped save the equipment while sacrificing themselves in the process. It is cheap insurance and makes perfect sense. |