|

In the

Feb. 1 issue, we discussed what

you'll find inside an electron tube

and its basic principles of

operation.

Now

let's talk about how that tube works

in an FM radio transmitter.

The key to amplification in a tube

is the control grid, the set of thin

wires between the filament and the

plate. You feed RF drive into this

grid, causing electron emission from

cathode to vary at the RF drive

frequency and amplitude. It is this

small voltage and power that

regulate a large electron flow at

much higher power. What we have been

talking about is a 3CX (triode)

tube.

|

|

Fig. 1: This is a

newly rebuilt transmitter

tube. |

Then

comes a fourth element, making the

tube a 4CX. It is called a screen

grid and is another wire grid

between the control grid and the

plate. Its job is to pull electrons

toward the plate with a positive

voltage. Most electrons go past the

screen grid and to the plate.

Some electrons are captured by the

screen grid and become screen

current. Yes, it is an unintended

consequence of being in the right

place at the right time.

If

you use a Harris or similar FM

transmitter you know that the power

control is a screen voltage control.

With no screen voltage, the

transmitter typically makes about 20

percent of its normal power. You

adjust screen voltage upward to

increase power. It is as simple as

that.

Each transmitter design is

different. Sometimes the control

grid in these designs has 100 or

more volts of negative DC to help

bring all the parameters together

for best performance and efficiency.

In

Continental FM transmitters, the PA

(power amplifier) plate voltage,

screen voltage and RF drive are

adjusted simultaneously with the

raise/lower power control. This is

an elegant design but does not

easily compensate for tolerance

differences between individual

tubes, especially as they age.

Engineers with Continental

Electronics transmitters find

themselves changing taps on the

screen transformer to accommodate a

new or rebuilt tube with slightly

different characteristics than the

last tube. The idea is to get the

volts to current ratio where the

transmitter manufacturer designed it

to be. Higher-screen voltage means

higher PA current. Those

transmitters also have a PA bias

control that will help with

tube-to-tube differences.

|

|

Fig. 2: Here's a

4CX20,000D tube in a Harris

FM transmitter. |

TUNING

You tune or "match" impedances

between the RF driver and the

control grid of the tube for minimum

reflected power to the RF driver.

Best not to try for maximum power

transfer as that could lead to

higher than desired reflected

power/VSWR on the driver stage. Tune

for lowest reflected power to keep

the driver stage happy. Then there

is power amplifier tuning where you

adjust for best tube efficiency by

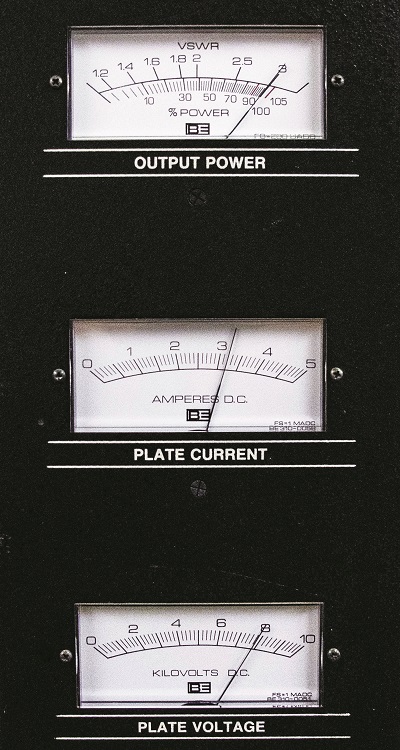

again matching impedances. Watch all

the meters, not just the power

output. Tune toward minimum PA

current while adjusting for maximum

power output. Adjust screen voltage

to keep the PA current where the

transmitter manufacturer says it

should be for your power level.Once you have adjusted for

best efficiency, use a thermometer

to verify that the exhaust

temperature of the tube is within

specifications. Output power meters

on transmitters are relative

devices. Every transmitter has a

control to set the meter to read

whatever you want.

Set it to read 100 percent only when

the transmitter is running

correctly. Never use the

output power meter to determine

operating power. You might have

higher or lower actual power than is

shown on the station license.

There is a little-used, FCC-approved

procedure for using the

transmitter's power meter, but few

stations are equipped to do so. You

can verify transmitter power with a

calibrated Bird or Coaxial Dynamics

brand wattmeter, if you like.

An

FCC inspector will look at PA

voltage, PA current and rated

transmitter efficiency to determine

if the station is running legal

power. The station will pass or fail

an inspection accordingly.

You will find PA efficiency listed

on the factory checkout sheet for

the transmitter or in a graph in the

transmitter instruction manual. An

example is 8,000 volts x 3.4 amperes

= 27,200 watts x 79.1 percent PA

efficiency = 21,515 watts of

transmitter power output. The

station license allows as much as 5

percent over that or 10 percent

under that to remain legal.

|

|

Fig. 3: Watch all

the meters, not just the

power output. |

TUBE TOO SMALL?

You have a 20 kW FM transmitter with

a 4CX15,000A tube. Does that make it

a bad design?No, the 15,000 watt tube

dissipation capability is for the

inefficiency of the power amplifier.

To put out 20,000 watts, the

transmitter might achieve 75 percent

PA efficiency. That means 26.7 kW of

high-voltage DC power is required to

enable the transmitter to achieve

20,000 watts of RF at its output.

The tube must lose 6.7 kW in heat

from the high-voltage supply plus

power lost in the control and screen

grid. Add to that the filament,

which is 6.3 volts at 160 amperes or

1,008 watts.

Eimac specifications show the tube

could develop as much as 36.5 kW

under the right conditions. That is

pushing the equation way too far, in

my opinion, and does not take into

account any mistuning. A transmitter

and tube might have to handle

antenna icing in winter conditions.

Poor matching because of that can

severely mistune a transmitter

causing the tube to dissipate more

power in an attempt to stay on the

air. Most transmitters have overload

and protection circuits to prevent

that.

FILAMENTS

Electron tubes wear out. The

filament is what wears. You've heard

it before, and I'll repeat it again.Best life from a tube comes

from proper filament management.

That means running the filament at

the rated voltage as indicated in

your transmitter manual or tube

specification sheet for 200 hours of

operation. Then drop it as low as

possible before there is a

significant reduction in emission,

which you see as lower transmitter

power.

You can easily double or triple a

tube's life by careful filament

voltage management. Some

transmitters have filament voltage

regulators to make up for power line

voltage variations. This is

especially helpful when power line

voltage sags frequently because of a

nearby factory or farm when electric

usage increases and decreases.

Tube emission and transmitter power

output will decrease as a tube nears

the end of its life. You should

adjust filament voltage upward to

compensate. It is time to replace

the tube when you are at 5 percent

over the rated filament voltage. It

is called "end of life."

PROBLEMS

If you have tuning trouble in a

transmitter, it is best to reduce PA

voltage or drive to keep the tube

within specification for

dissipation. If you look in a tube

spec book, you will see figures for

maximum control and screen grid

dissipation too. Sometimes, I've

disconnected one of the three leads

on the primary of a three-phase

power transformer when tuning and

troubleshooting. Do this with all

the power turned off! Typically the

PA voltage will drop to half. That

will put the output at one-quarter

power. Do the troubleshooting and

initial tuning before reconnecting

that third wire. That is a great way

of handling a problem without

burning up a tube.

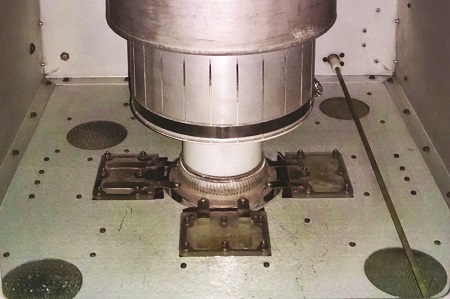

|

|

Fig. 4: A tube

cavity with 4CX20,000C |

MORE IS NOT BETTER

This is for transmitters with

solid-state RF drivers.

Just

because an FM transmitter

manufacturer recommends the PA tube

in your transmitter needs 350 watts

of drive, it doesn't mean that 400

watts is better. You can get into a

situation where PA efficiency will

suffer with more RF drive.

Do

your tuning to match what the

manufacturer test data shows. Your

numbers may be a bit off because you

have a different tube in the

transmitter. Adjust RF drive by

tweaking FM exciter power. You will

find that the tube efficiency is

poor when under driven. It will peak

and then drop off again as drive is

increased.

Find the sweet spot where PA

efficiency is best. You will know

that when PA current is low and

transmitter RF output is highest.

RECORD KEEPING

Keep tabs on what condition your

tubes are in when removed from

service.

You can

refer to a serial number on the

bottom, which is often difficult to

read.

Another way is to mark the tube with

a statement something like "makes 90

percent power." Do not mark on

the ceramic. Yes, ceramic is a

wonderful place for a pencil to

leave legible markings. Pencil lead

is a conductor and can easily help

start an arc-over when the tube is

returned to service. Pencil lead is

also difficult for a tube rebuilding

company to remove. Best to use a

liquid pen and indicate status on

the tube anode.

You'll be glad you did when you

return to a broken transmitter in

the middle of the night and can�t

remember which tube is good and

which one isn't.

DO IT RIGHT

My recommendation: Have one new or

rebuilt tube on the shelf for every

tube that is in service at the site.

Tubes are "wear" items and will wear

out or outright fail with time. It

is just a matter of when.

You

can't predict when a tube will need

replacing. Yes, a tube can get weak

so transmitter power falls off. It

can just quit in just seconds,

putting you in a bind to get a

replacement in a hurry.

Knowing the facts will help you get

the job done right.

Mark Persons W0MH is

Certified Professional Broadcast

Engineer by the Society of Broadcast

Engineers and has more than 30

years' experience. His website is

www.mwpersons.com. You can also see this article at

Radio World Magazine:

http://www.radioworld.com/article/going-tubing-find-the-sweet-spot/274894 |