|

What do you do when a

high-voltage blocking

capacitor in an FM

transmitter fails?

We are talking about the

large cylinder that

surrounds a tube. It is

actually one aluminum

cylinder within another,

with insulating (dielectric)

material in between. The

purpose is to transfer RF

energy from the tube anode

to the output-tuning network

without shorting

high-voltage DC to ground.

That direct current often is

connected directly to the

tube via a clip on the

anode.

So there you are with a

shorted blocking capacitor

and no replacement on the

shelf. (Why would the

station have a spare when

they fail only once in 20

years or so?)

My story goes back to a cold

day in January, when it took

a farm snowplow to clear a

road to a transmitter site

(Fig. 1). Such is life in

Minnesota during the winter.

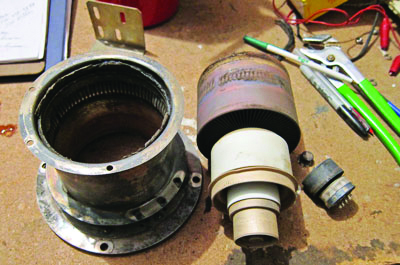

Fig. 2 shows the charred

remains of a PA tube, a

driver tube and a

high-voltage blocking

capacitor from a CCA FM2500B

FM Transmitter. The normal

tube appearance is of

nickel-plating, not

brown-red. The blower motor

quit, but the transmitter

kept running when the

airflow switch stayed in the

on position. The switch

worked normally when tested

a year before, so I can only

assume it stuck from being

on for a long time.

|

|

| Fig. 2:

These items have

overheated. |

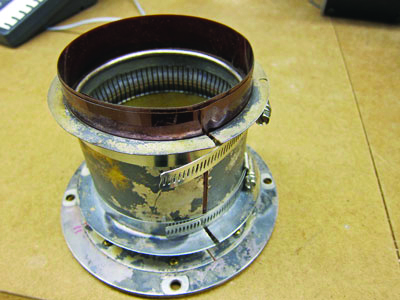

Fig. 3:

Hacksaw the outer

cylinder. |

NO SPARES

This transmitter normally

runs 2,200 watts using a

3CX400A driver tube and

3CX3000A7 PA tube. The

client keeps spare tubes on

the shelf so that was not a

problem, but who keeps an

extra blocking capacitor?

Since there was no spare,

the only option to avoid two

days of off-air time was to

rebuild the original

capacitor. This particular

type of capacitor was not

designed for rebuilding, but

what else was there to do?

It�s not rocket science!

I took the capacitor to the

shop and used a hacksaw to

cut through the outer

cylinder and just into the

dielectric between the outer

and inner cylinders.

|

|

| Fig. 4:

Note the arc-over

spot. |

Fig. 5:

Clean to smooth

rough edges. |

After unwrapping and

exposing the original

dielectric, I found an

arc-over spot. Now the real

work began.

Plenty of cleaning was

needed to get sharp edges

and other blemishes down to

prevent future arc-overs. A

file and 3M Scotch-Brite

scouring pads worked well

here. I remember hearing of

someone who replaced

dielectric material without

removing the sharp edges,

only to have the same arc

problem immediately again!

I found new Kapton

dielectric material on the

shelf at a nearby station

and wound it onto the inside

cylinder of the blocking

capacitor; then the outer

cylinder was put back on.

This thin Kapton sheet is

4-3/4 inches wide and is

used by Continental

Electronics in its

transmitter blocking

capacitors. At less than $90

from Continental, it is

worth keeping some on the

shelf. A complete blocking

capacitor, which includes

the two metal cylinders,

costs $450 to $1,500

depending on which

transmitter and manufacturer

you order one from. Kapton

has a reddish-brown color,

as opposed to the original

clear-white, which was

probably Teflon, in this

case.

|

|

| Fig. 6:

Use some of the

Kapton material you

keep on the shelf. |

Fig. 7:

Measure capacitance

to confirm it is

right. |

The original capacitor

had six turns of dielectric

sheet, but capacitance

testing, using a Sencore Z

Meter, showed that was one

turn too many with this new

material.

TESTING

The proof is in the

capacitance of the assembly.

Here the rebuilt blocking

capacitor measures very

close to the original 550

pf. Yes, I was able to

determine the capacitance of

the original shorted

capacitor because testing

was with just a few volts,

rather than the normal 4,000

volts in the transmitter.

Two stainless

steel hose clamps were used

to hold the outer cylinder

tight on the dielectric.

Stainless is not

ferromagnetic. I pointed

this out in a December 2013

article in Radio World (Fix

a Transmitter Tube Socket,

radioworld.com,

keyword Socket). This is

important as anything that

is attracted by a magnet in

a high RF field will tend to

vibrate at the RF frequency

and sometimes melt. Use an

ordinary small magnet to

verify that nothing in the

RF area is attracted

magnetically.

|

|

| Fig. 8:

Here's the

reassembled blocking

capacitor. |

and

the blocker is back

in the transmitter. |

Fig. 9 shows the final

assembly, back in the

transmitter, just before

high voltage was turned on.

Yes, the outer parts of the

blocking capacitor have an

oxidized appearance. They

are silver-plated and get to

look that way from years of

exposure to air. The

oxidation does not hurt

transmitter performance.

Success � no arcs and the

operating parameters came

back to normal.

This is a permanent fix for

the problem and the blocking

capacitor is more repairable

if this should happen again

in the future. It makes

perfect sense.

Mark Persons, W0MH, CPBE, has over 30 years

experience. He has written

numerous articles for

industry publications over

the years. His website is

www.mwpersons.com. |